apt Group Invests in Most Modern Extrusion Technology

With a yearly production capacity of 80.000 tons apt Group belongs to the leading European aluminium profile manufacturers. The competence of apt‘s extrusion division with production facilities in Monheim am Rhein (D) and in Roermond (NL) are complemented by its products division with two state-of-the-art fabrication centres in Eckental (D) and Cheb (CZ) where further processing activities for customers from the automotive, commercial vehicle and industry sector are located.

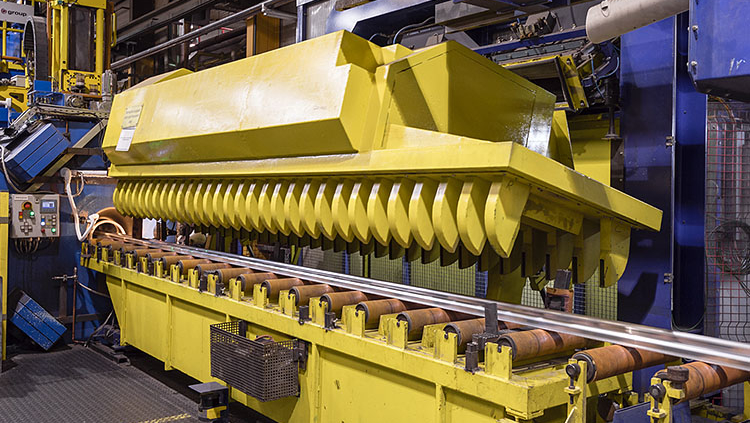

Within apt’s extrusion plant in Monheim the former 2,000 tons (20 MN)-press was replaced with a new modern front-loading press of SMS, which has an extrusion force of 27 MN. Additionally, the billet furnace was renewed. Furthermore, new automatic sawing lines were installed at both extrusion facilities.

“Despite a challenging investment environment in Germany and the Netherlands, which is mainly caused by high energy- and personnel costs, apt has repeatedly proven to maintain its competitiveness by investing in most modern technologies. In this way, the future of these locations is sustainably secured.”, explains Bernd Schäfer, CEO of the group.

With 27 MN extrusion force, the new press is bigger than the previous one and meets market requirements. In order to use the efficiency of the press in the best possible way, billet diameters were adjusted accordingly. Thanks to the configuration of the new 27 MN press and its parameters, further synergy and backup potential has been generated between the two extrusion plants in Monheim and Roermond.

In the context of the investment into the P27, apt installed for the first time a billet heating in conjunction with an induction furnace. Another novelty is the hot-sawing process of the billets. In essence the advantages of the new press can be identified in the combination of inline-furnace, front-loading press, extreme cooling system and flying cutting:

The furnace stands out with an exact temperature control. This results in a consistent product quality. Since billets are cut, the system is significantly less sensitive to failures. The material data can be traced precisely. Further, the block magazine results in a more efficient logistic process. Up to 150 bars can be stored near the press and are automatically fed into the process.

The new press also provides substantial advantages: The linear guidance of punch and recipient results in further improved process reliability. Shortest auxiliary process times are achieved by the instalment of very fast hydraulics. The new press operates with an ecodraulic system, an intelligent start/stop automatic to shut down unused hydraulic pumps. The block diameter was increased to 215 mm, leading to higher efficiency in logistics and procurement.

The extruded profiles receive better mechanical properties thanks to an extreme cooling system. This system ensures an optimized cooling process for asymmetrical cross-sections and greater tolerances for demanding alloys. Flying cutting causes a reduction in auxiliary process times and in process scrap.

„Altogether, the investment into the new press leads to energy savings and a significant increase in productivity, process reliability, and quality. Furthermore, the additional investments in sawing competences at the Monheim and Roermond location are an additional step towards optimized workflows. Our employees benefit from ergonomic working conditions at highest possible safety levels.”, emphasizes Bernd Schäfer.

The 2017 installed automatic saw in Monheim has a feeder-magazine where raw lengths are placed in packages. The profile package is gripped by a clamping unit and then pushed through the saw. The feed drive is generated through a highly dynamic linear drive. In this way, profiles are placed precisely, resulting in a higher throughput rate. Due to short change times, the machinery is highly flexible and produces lengths between 10 mm and 3,500 mm.

The newly installed automatic saw at apt Extrusions B.V. in Roermond is characterized by extremely tight tolerances. This machine has been designed to fit the specific needs of apt in Roermond. It fulfills current market requirements and complements the existing line up. Many customer orders from the commercial vehicle sector are already produced with this saw. The very tight tolerances that can be achieved are also interesting for other industries and new customers.

apt Group is divided into its business units aluminium extrusion and fabrication. About 1,000 employees generate yearly revenues of approximately 250 million Euros. apt belongs to the market leaders in the west-European aluminium industry with six extrusion lines, state of the art fabrication, and three anodizing plants. Renowned customers from the building, transportation, and industry sector are supplied. The product portfolio includes complex aluminium profiles, which are partly postprocessed and refined, as well as aluminium products and systems.