Reduce costs, save weight –

with lightweight flaps for your coaches

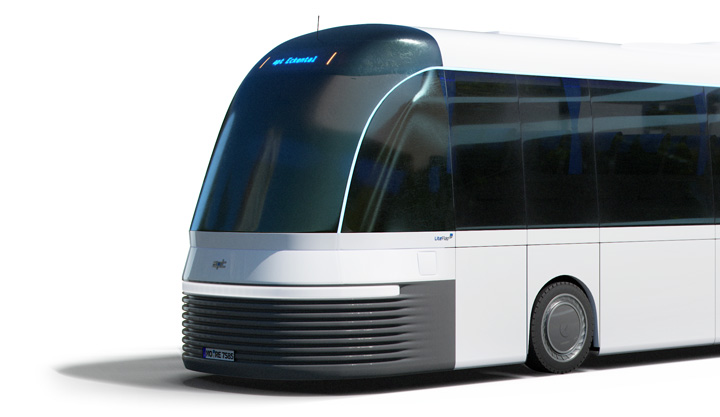

Whether it’s a luggage compartment flap, ventilation flap, fuel filler flap or overrun flap, you can significantly reduce the weight of flaps on coaches and intercity buses with the LiteFlap lightweight design concept from apt. The unique design saves up to 38% of the usual weight, thereby reducing costs, material consumption and CO2 emissions. The flaps, which are made entirely of aluminum, are made in Germany and thus promise reliably high quality and short delivery times. The flaps can be adapted to your design concept and fit seamlessly into the overall concept of your bus.