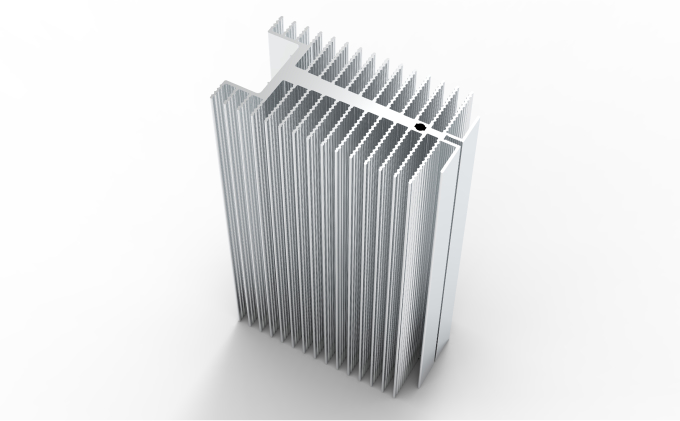

Efficient aluminum heat sinks

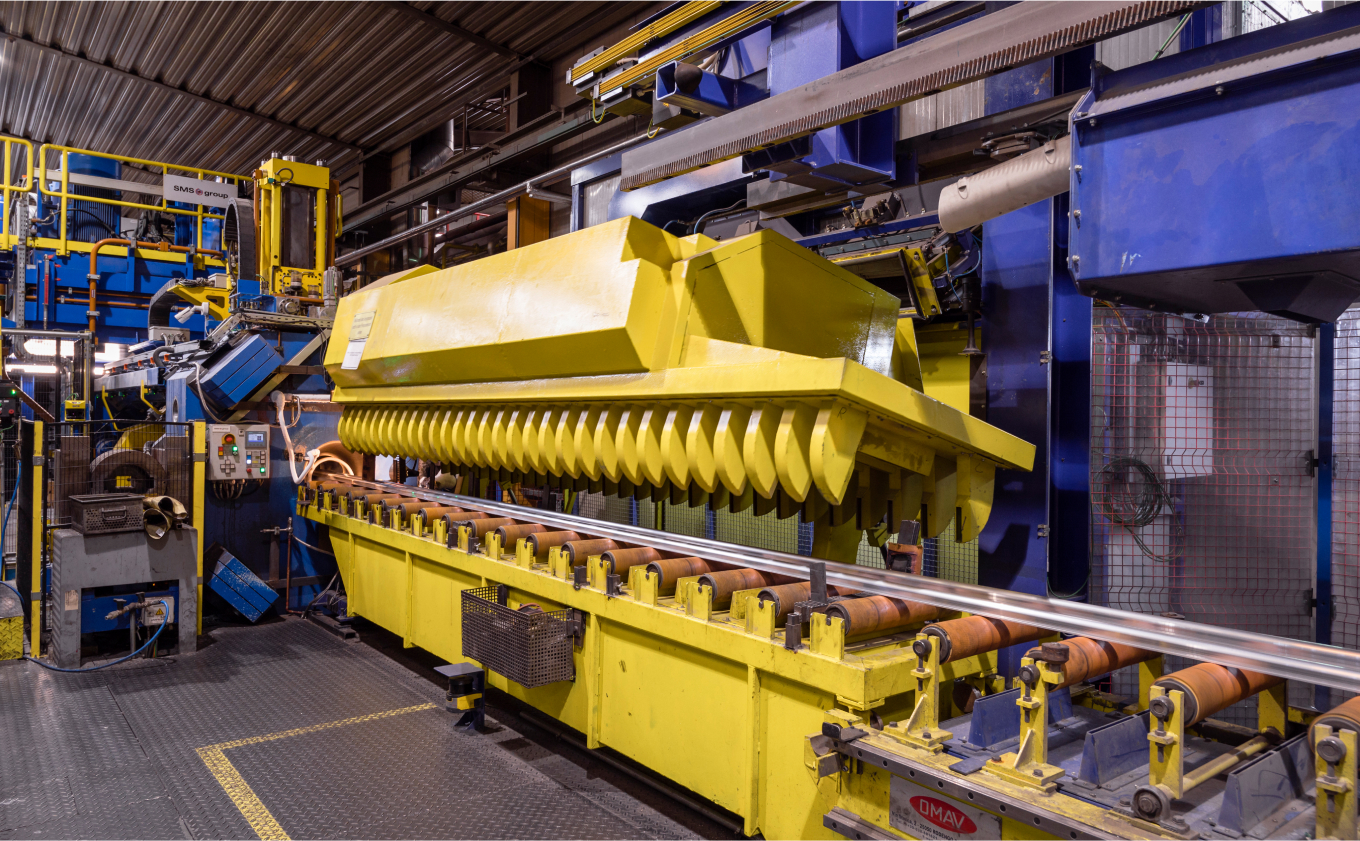

Extrusion technology for precise and sustainable heat dissipation

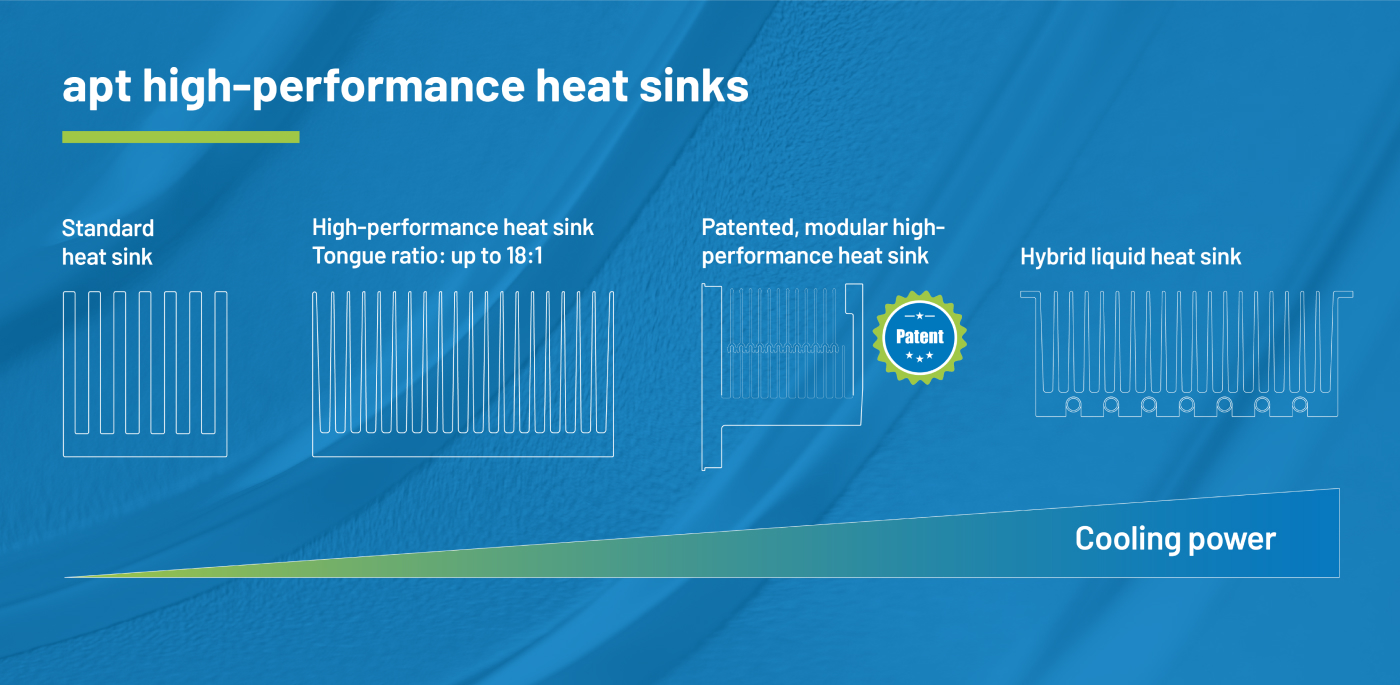

The demands on power electronics have risen dramatically across many industries. Electronic components are becoming increasingly powerful, requiring highly efficient thermal management. A critical factor: high-performance heat sinks that effectively dissipate heat in limited space while offering a sustainable and cost-efficient solution.

To meet these technical requirements, we manufacture heat sinks that ensure maximum cooling performance with reduced material consumption and sustainable design.