Extruded aluminum profiles

Precise, individual and sustainable

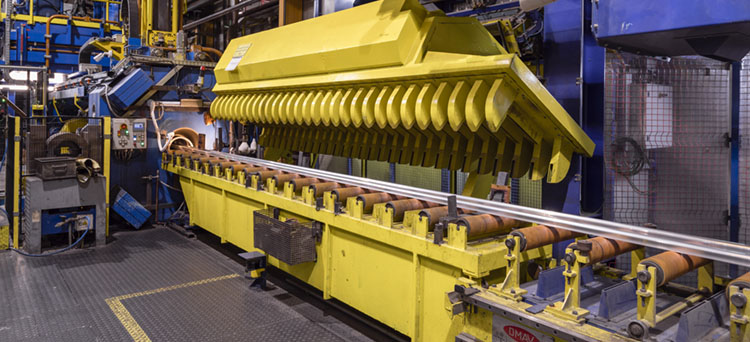

Complex shapes, precise results – we are your partner for extrusion. As a manufacturer, we produce extruded profiles precisely tailored to your requirements. To do this, we rely on innovative and fully automated process technology to keep the carbon footprint low during distribution. For optimal results, we support you in all production steps: from consulting & co-engineering to prototyping and efficient series production. Thanks to these strengths, we press 80,000 tons of aluminum annually for customers internationally on our six high-tech extrusion lines.