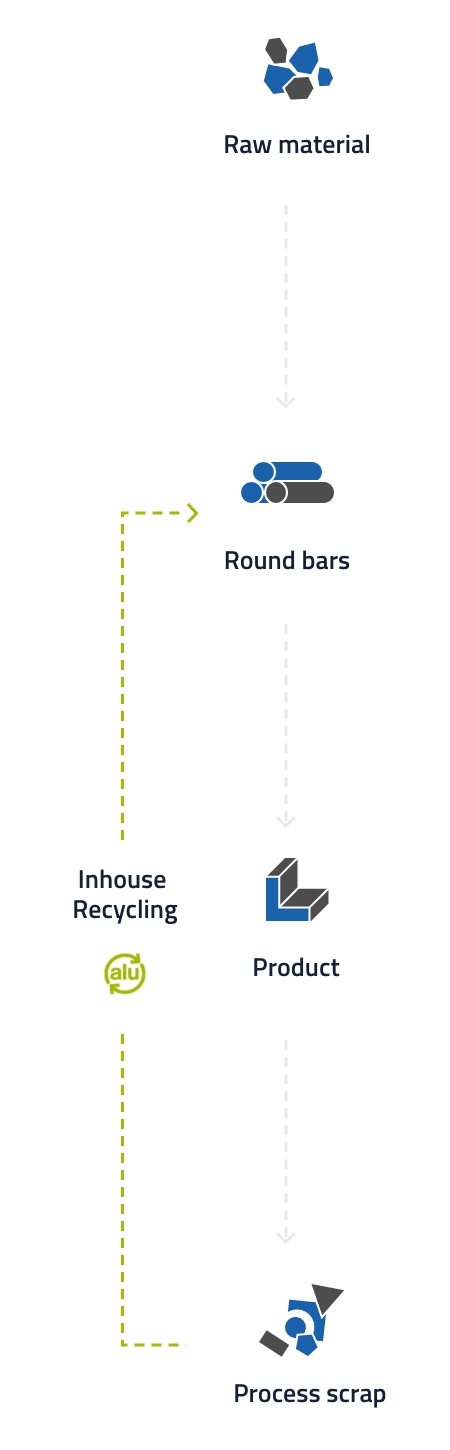

Our own remelting for recycling

Billets from aluminium process scrap

Recycling quality just like primary aluminium

Within the apt Group, we operate our own foundry to reprocess any aluminium extrusion process scrap incurred. These are recycled in house and remelted into billets before being reintroduced to our processing system. Our strict quality management system ensures that the produced round bars meet the highest quality requirements. These billets are not inferior to primary produced aluminium, either in the composition of alloys, or in their material characteristics. We can recycle up to 18,000 tonnes of aluminium every year.